Technical information

| Output |

Up to 160 upm |

Crimped pumps

Crimpless pumps

Screw-on pumps

Clinch-on pumps

(for deodorant cans)

Mini-pumps

Drop dispensers / Checkers |

Ø 11 to 20 (actuator pre-assembled or not)

Ø 11 to 30 (actuator pre-assembled or not)

Ø 11 to 30 (actuator pre-assembled or not)

Up to Ø 30

actuator pre-assembled or not

Ø 11 to 20 |

Length of dip-tubes

Pump body height |

30 mm to 160 mm

Up to 40 mm |

| Motor |

Prefeed elevator :

0,13 kW |

| Power |

Power : Tri 380V + N + Ground 50/60Hz Control 220 V |

| Hopper work height |

1,050 mm |

| Size

Bowl only

Bowl with prefeed elevator |

Width : 1000mm

Depth : 2000mm

Height : 1500mm

Width : 1000mm

Depth : 3000mm

Height : 2100mm |

| Sound level |

< 70 dBA |

|

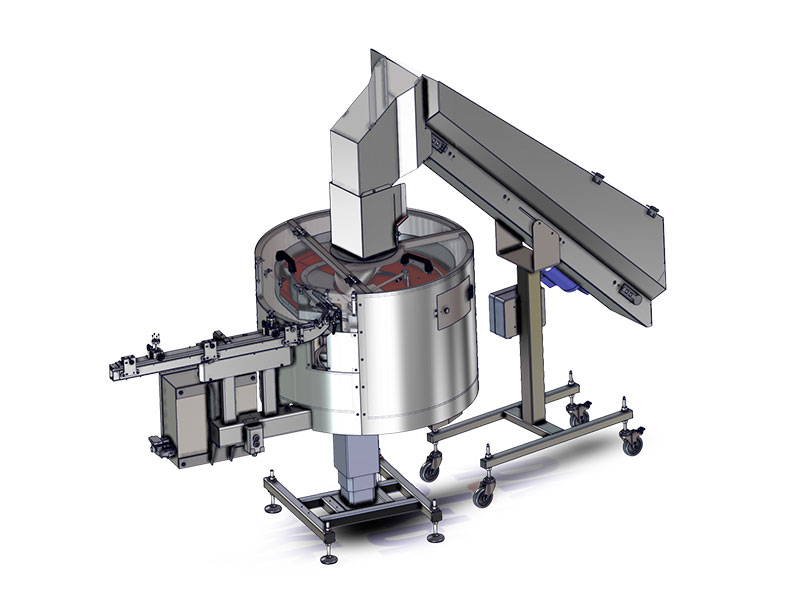

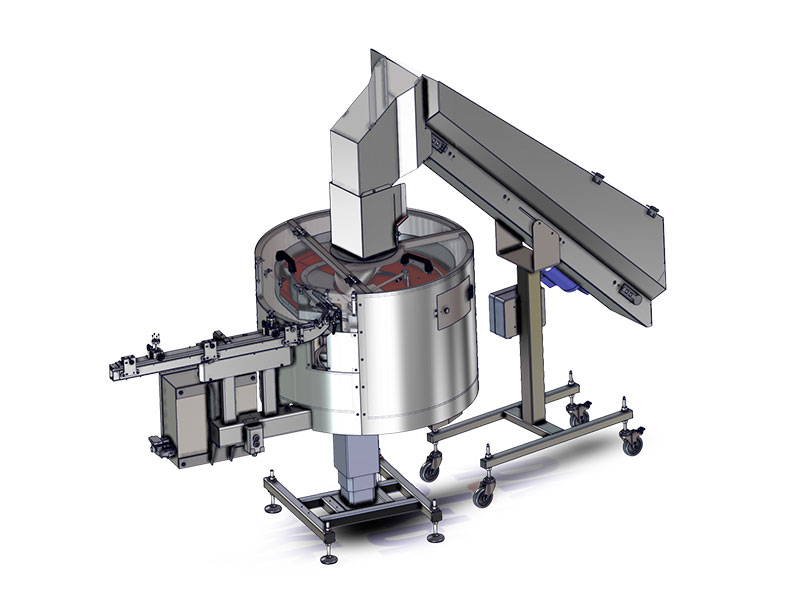

PERFUME PUMP MULTI-FORMAT HIGH SPEED VIBRATING BOWL

The NEW GENERATION high performance perfume pump patented PKB vibrating bowls are extremely easy to use, with quick and easy format changeovers using only one bowl for all the different types and sizes of perfume pumps.

- High outputs: up to 160 units/minute,

- No air jets (no compressed air, reliability, repeatable format changeovers, reduced noise, reduced operating costs), patented device,

- Great sorting quality and a high degree of respect for the integrity of the items being dispensed all due to the effective design of the specialized vibrating bowl, dedicated exclusively to perfume pump sorting.

- Quick and extremely simple tool-free format changeovers, no bowl to change, minimum adjustments and format parts, easy to empty bowl,

- Multi-format universal rail guide,

- Industrial production of all components for this new bowl, particularly the format parts (100% machined),

- Over 60-minute autonomy,

- Very robust, ergonomic design and minimum maintenance,

- Guards designed specifically for maximum acoustic insulation,

- Flexibility in terms of layout (thanks to the standard double-blade technology of the vibrating rail, allowing for very long rail guides if necessary),

- Clear, user-friendly bowl manual,

- Bowl certified to CE standards by an independent accredited organization,

- PKB is currently the only manufacturer of vibrating bowls having obtained explosion-proof ATEX zone 1 certification for its vibrating bowls and rails after a long and costly process,

- Prefeed elevator to increase autonomy,

- Adjustment of the perfume pump vibrating bowl height (with the option of synchronizing height adjustment in conjunction with the connected machine),

- Additional prefeed elevator, adjustable at 180° for optimal use passing underneath the conveyor (to feed the pumps from the inside of the line).

|

Back

Back